Minealytics is a vendor agnostic, fully integrated, plant AI

Minealytics is uniquely positioned to be a key catalyst in realising data-driven mining through its suite of AI technologies and services.

-

Comprehensive Data Integration

Minealytics excels in integrating disparate data sources from various mining operations into a cohesive, easily accessible platform. This integration allows for a holistic view of operations, enabling better decision-making and operational oversight.

-

Advanced Analytics

Leveraging state-of-the-art analytics tools, Minealytics can process and analyse the vast amounts of data generated by mining operations. This analysis can uncover valuable insights into efficiency, productivity, and potential areas for improvement.

-

Predictive Maintenance and Operation Optimisation

By applying machine learning and predictive analytics, Minealytics helps mining companies anticipate equipment failures, optimise resource allocation, and streamline operational processes, reducing downtime and increasing overall efficiency.

-

Nerual Control

Minealytics' expertise in AI provides tailored solutions for autonomous control systems and intelligent decision-making processes. These AI-driven solutions can automate routine tasks, optimise complex operations, and enhance safety measures.

-

Mine Artifical General Intelligence

The Minealytics AGI's core mission is to continuously assess plant health and production performance, identifying inefficiencies and potential failures before they escalate. Armed with this insight, it proactively recommends adjustments to plant setpoints and operational strategies to optimize throughput and minimise downtime.

-

Enhancing Decision Making

Through advanced data visualization tools and dashboards, Minealytics transforms complex data sets into actionable insights. This empowers decision-makers to base their strategies on solid, data-driven insights, leading to more effective management of operations.

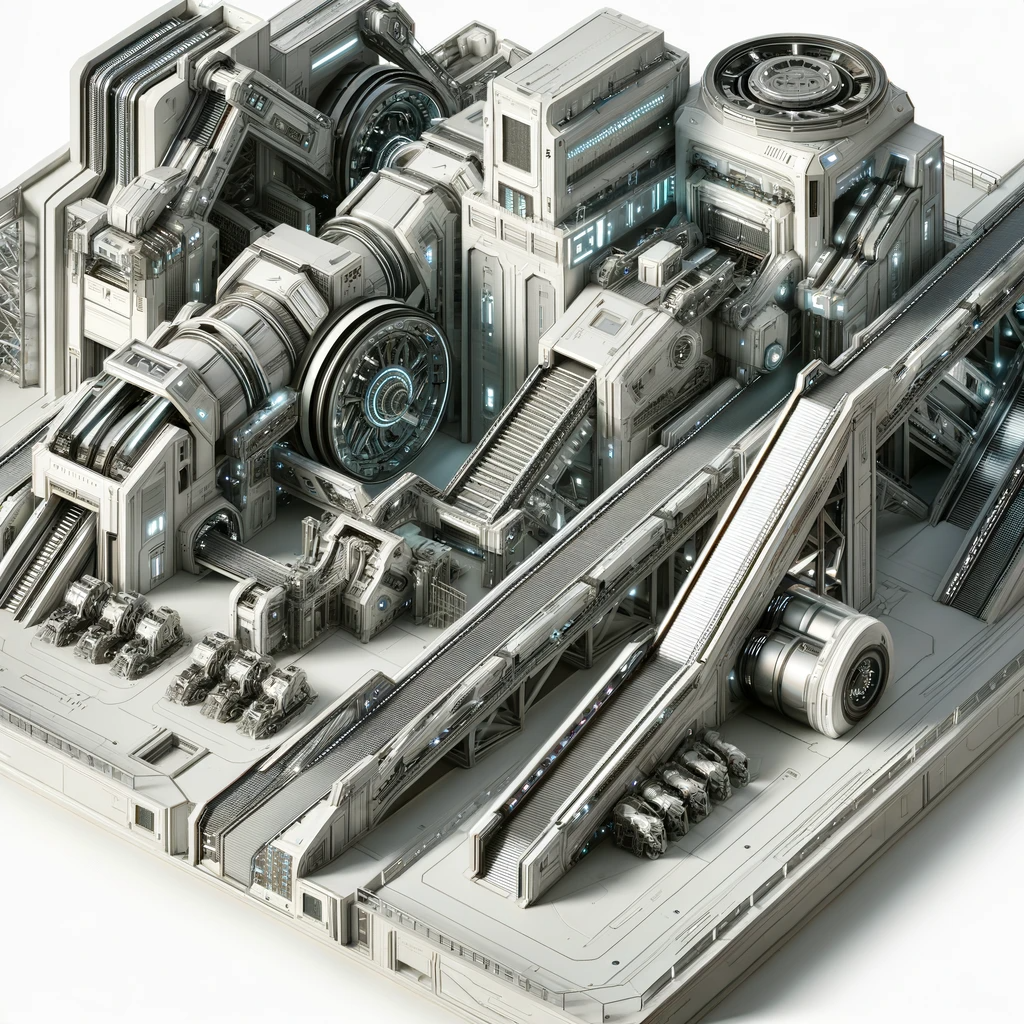

Advanced Process Control

Minealytics is a pioneering force in the mining industry, specialising in Analytics and Advanced Process Control services. Leveraging the power of cutting-edge artificial intelligence and computer vision technologies, we provide comprehensive, data-driven solutions tailored to enhance operational efficiency and safety. Our expertise in analytics enables us to extract valuable insights from complex data, optimising decision-making processes. Meanwhile, our advanced process control systems revolutionise traditional mining practices, paving the way for smarter, more autonomous operations. With Minealytics, mining companies can anticipate a significant transformation in their operations, marked by increased productivity, reduced costs, and a stronger commitment to environmental sustainability.

Computer Vision

Minealytics is at the forefront of revolutionising the mining industry with its state-of-the-art Computer Vision products. Our CV solutions harness the power of AI-driven image and video analysis to provide unprecedented insights and automation capabilities in mining operations. From real-time monitoring of equipment and materials to the detection of operational anomalies and safety hazards, our Computer Vision technology is engineered to enhance precision, efficiency, and safety. This innovative approach not only optimises the extraction and processing stages but also plays a crucial role in environmental monitoring and compliance. By integrating our Computer Vision solutions, mining companies can expect a significant leap towards smarter, more sustainable, and future-ready operations.

Neural Mine Control

Minealytics is leading the transformation of the mining industry with its AI-based Autonomous Mine Control services, a cutting-edge solution designed for the modern mining landscape. Our services leverage artificial intelligence to orchestrate and optimise mine operations, bringing a new level of efficiency and intelligence to the sector. By employing advanced algorithms and machine learning, Minealytics offers a fully integrated, autonomous, real-time control system that manages everything from resource allocation to equipment operation, ensuring optimal performance and productivity. This system not only significantly reduces the need for manual intervention but also enhances safety by minimising human exposure to hazardous mining environments. Our autonomous control services represent a significant step towards a more sustainable, profitable, and technologically advanced mining industry, promising a future where mines operate with greater precision, reduced environmental impact, and enhanced profitability.